Drilling NPT-Prevention Agent: Stop losing days to surprises

Introduction

A Drilling Non-Productive Time (NPT) Prevention Agent continuously monitors real-time drilling signals, reads Daily Drilling Reports (DDRs), retrieves lessons from offset wells, and generates action-ready alerts— while keeping all operational decisions human-led.

What problem are drilling teams facing?

Non-Productive Time (NPT) is time spent on drilling activities that do not move the well forward. NPT can be caused by equipment issues, wellbore instability (for example, stuck pipe), waiting on decisions, or operational rework. Many rigs capture time categories in Daily Drilling Reports (DDRs) using consistent coding guidance such as the International Association of Drilling Contractors (IADC) DDR Codes.

Why NPT happens (even with experienced teams)?

- Real-time signals are high-volume and easy to miss during busy shifts

- Context is spread across sensors, DDR narratives, offset wells, and documents

- Shift handovers can lose the “story” behind subtle changes

- Teams may act after the problem becomes obvious rather than early

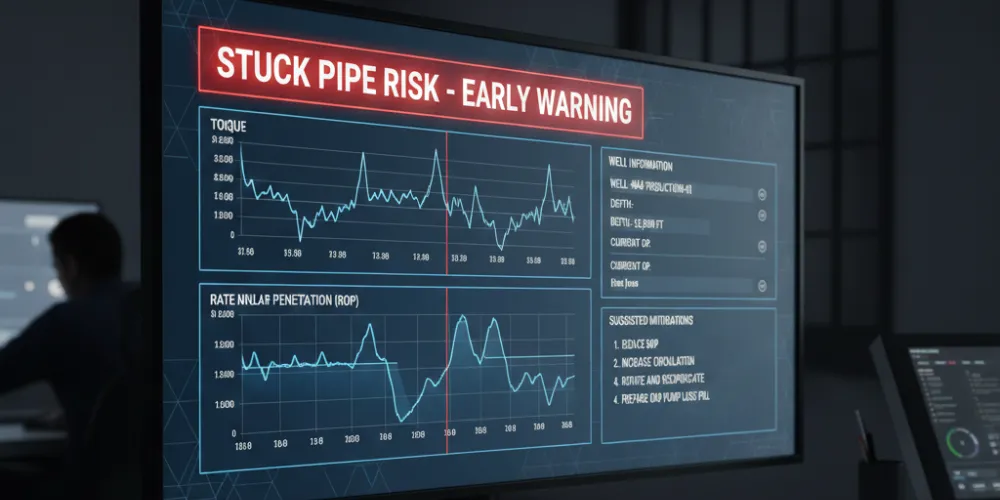

What “early warning” should mean?

- Detect trend shifts (not only threshold alarms)

- Explain “why now” in plain language

- Attach evidence: time window + signals + notes

- Suggest mitigations aligned to approved practices.

💡 Bottom line: The rig already produces enough signals to prevent many issues. The hard part is converting signals intofast, consistent, evidence-backed decisions

What is the current manual solution used today (and why it’s costly)?

Today, most drilling teams rely on a mix of dashboards, shift calls, and expert judgment. This works—but it becomes time-intensive and resource-consuming as data volume grows and teams operate across rigs and time zones. Reporting is often structured through Daily Drilling Reports (DDRs) (see IADC DDR Codes), and live drilling data is frequently exchanged using standards like Wellsite Information Transfer Standard Markup Language (WITSML).

What teams do manually?

- Watch multiple real-time dashboards and alarm lists throughout the shift

- Read and write DDR narratives to explain events and time breakdowns

- Search old wells (offset wells) for similar symptoms and what worked

- Hold calls between rig, drilling engineer, and Real-Time Operations Center (RTOC)

- Decide actions under time pressure and document the outcome later

Why it consumes time and resources?

- Context switching: people jump between tools, reports, emails, and spreadsheets

- Knowledge is tribal: best practices live in expert heads or scattered PDFs

- Slow retrieval: finding similar cases can take hours during an incident

- Inconsistent decisions: two shifts may react differently to the same pattern

- Delayed learning: outcomes don’t always loop back into future shift decisions

💡 Result of the manual approach

Even when teams do everything right, this model can createlate escalation,repeat issues across wells and high coordination overhead-especially when remote monitoring expectations increase (see BSEE Real-Time Monitoring (RTM) best practices).

How can Agentic AI + GenAI solve those manual pain points?

A Drilling NPT-Prevention Agent behaves like an always-on co-pilot. It monitors real-time drilling data, reads text from DDRs and shift notes, retrieves similar historical cases, and generates a structured alert. When operators expose real-time and well data via standards like Wellsite Information Transfer Standard Markup Language (WITSML) from Energistics, the agent can connect data sources more reliably.

Front: Detect

severity + confidence.

Back: Evidence

No evidence → no claim

Front: Retrieve

Back: Explain

Engineer stays in control

Front: Suggest

Back: Escalate

Audit trail included

💡 What the agent replaces (from the manual flow)

It reduces context switching by combining: (1) trend detection, (2) fast retrieval of similar cases, and (3) a standard alert format with evidence. Humans still decide the action.

How does it look in real implementation?

In the field, the agent usually supports rig teams and the Real-Time Operations Center (RTOC). It does not control equipment. It generates evidence-backed alerts and recommended next actions. For U.S. context on real-time monitoring practices and governance, the Bureau of Safety and Environmental Enforcement (BSEE) Real-Time Monitoring (RTM) best practices report (PDF) is a helpful reference.

Deployment flow (simple)

- Ingest live parameters + DDR notes + offset well documents

- Detect early risk patterns and assign severity/confidence

- Retrieve similar cases and proven mitigations (RAG)

- Generate an alert with “why now” + recommended next steps

- Human review → decision → outcome logged for learning

What an alert should include?

- Risk type: stuck pipe developing (example)

- Evidence: torque trend + pressure change + rate of penetration drop

- Context: hole section, Bottom Hole Assembly (BHA), mud properties

- Suggested actions: aligned to runbooks / proven mitigations

- Escalation: notify drilling engineer + superintendent if risk increases

Reference tech stack (high level)

Exact tools vary by operator, but the pattern is consistent: data integration → detection models → retrieval + reasoning → alerting + audit.

Data & integration layer

- WITSML ingestion gateway + normalization

- Time-series store (rig sensors, mud logging, Measurement While Drilling / Logging While Drilling)

- Document store (DDRs, post-well reports, lessons learned)

- Well master data and metadata (rig, section, BHA)

AI & orchestration layer

- Anomaly detection + risk classification models

- Retrieval-Augmented Generation (RAG) grounded in approved documents

- Agent orchestration (multi-step workflow + guardrails)

- Confidence scoring + explainability + audit logs

💡 Practical rollout tip

Start with “shadow mode” (alerts generated but not acted on). Once engineers trust the evidence quality, move to assistive alerts in live operations.

Pilot scorecard (baseline vs agent)

Start with measurable operational outcomes—not just model metrics.

Operational metrics

- Time-to-detect (pattern start → alert)

- Time-to-decision (alert → action logged)

- NPT hours avoided (engineer-validated)

- Reduction in repeated issues across wells/sections.

Quality metrics

- Engineer usefulness rating per alert (1–5)

- Percent of alerts with attached evidence + explanation

- False alarm rate + safe dismissals (with reason)

- Recall on known precursor patterns (if labeled)

Safety & governance guardrails

The agent must remain assistive. Humans approve operational changes. Every alert should be traceable and auditable.

Guardrails (non-negotiable)

- Human-in-the-loop approvals for changes to operations

- Role-based access control (RBAC) for data and actions

- “No evidence → no claim” policy

- Full audit log (alert → decision → outcome)

Why this improves safety

- Earlier awareness reduces emergency response conditions

- Consistency across shifts reduces handover misses

- Evidence-backed alerts reduce “guesswork pressure”

- Stronger learning loop improves future wells

Partner With Us

At AI India Innovations, we see drilling agents as a foundational tool for next-generation autonomous systems and edge AI applications.

With Gen AI and Agentic AI projected to exceed $155 billion by 2030, frameworks like Drilling NPT Prevention agents are not just tools-they’re the engines driving the future of the field. You can read about our works in our Blogs section on our page. Happy Reading!